- Hotline:

- +86-15851956577

Category: Drying equipment

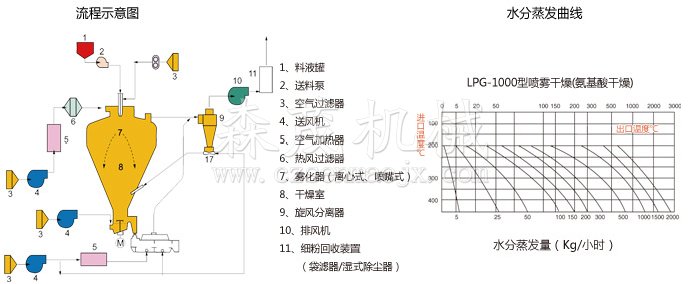

Introduction: Product IntroductionSpray drying is widely used in liquid forming and drying industries. It is especially suitable for generating powdery and granular solid products from solution, lotion, suspension and paste liquid raw materials. Therefore, when the…

| Model/Project/Parameters | 5 | 25 | 50 | 150 | 200-2000 |

| Inlet temperature | 140-350 automatic control | ||||

| Outlet temperature | 80-90 | ||||

| Upper limit of water evaporation(kg/h) | 5 | 25 | 50 | 150 | 200-2000 |

| Drive type of centrifugal spray head | Compressed air transmission | mechanical drive | |||

| Upper limit of speed(r.p.m) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| Spray disc diameter(mm) | 50 | 120 | 120 | 150 | 180-240 |

| heat source | electricity | Steam+Electricity | Steam+electricity, fuel oil, gas, hot air stove | ||

| Upper limit of electric heating power(kw) | 9 | 36 | 72 | 99 | |

| Overall dimensions (length × wide × High)(m) | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.5×3.5×4.8 | 5.5×4×7 | Determine based on actual situation |

| Dry powder recycling(%) | ≥95 | ||||

Note: The evaporation of moisture is related to the characteristics of materials and the temperature of hot air inlet and outlet. When the outlet temperature is 90oC, the water evaporation curve is shown in the above figure (for selection reference). As the product is constantly updated, relevant parameters are subject to change without prior notice.

| size | A | B | C | D | E1 | E2 | F | G | H | I |

| LPG-25 | 1290 | 3410 | 4260 | 1800 | 1200 | 1200 | 1000 | 1700 | 1300 | 1550 |

| LPG-50 | 1730 | 4245 | 5100 | 2133 | 1640 | 1640 | 1250 | 1750 | 1800 | 1600 |

| LPG-100 | 2500 | 5300 | 6000 | 2560 | 2100 | 2100 | 1750 | 1930 | 2600 | 1780 |

| LPG-150 | 2800 | 6000 | 7000 | 2860 | 2180 | 2180 | 1970 | 2080 | 3050 | 1960 |

| LPG-200 | 2800 | 6600 | 7300 | 3200 | 2300 | 2300 | 2210 | 2250 | 3050 | 2100 |

| LPG-300 | 2800 | 8000 | 8700 | 3700 | 2800 | 2800 | 2520 | 2400 | 3040 | 2250 |

1. Increase the temperature of hot air entering the towerUnder the condition of constant outlet temperature, the higher the inlet temperature (also known as inlet temperature) of the hot air, the higher the total heat brought in. The more heat per uni…

1. Flash dryer raw material acceleration and drying stageIn the heat transfer medium, particles are at a higher temperature and the air humidity is below 100%. In a short period of time, the surface is heated to the dry material humidity, and the rate…

▲ The flash dryer has multiple feeding devices to choose from, ensuring continuous and stable feeding without any bridging during the process.▲ A dedicated cooling device is installed at the bottom of the flash dryer to prevent material deterioratio…

The internal influencing factors of the efficiency of hollow blade dryers.1. Mixing blade qualityWhen the mixing blades in the hollow blade dryer are damaged, it will seriously affect the working efficiency of the hollow blade dryer. Without the mixin…

A hot air circulation oven is a device that uses circulating hot air to achieve a drying effect. There are generally five models of hot air circulation ovens. They are single door bicycles, two door two cars, two door four cars, three door six cars, a…

The disc dryer is suitable for use in drying projects with high evaporation intensity. On the basis of the basic configuration, a finned heater is added to introduce small flow of hot air into the dryer, absorb the water vapor that escapes from the ma…