- Hotline:

- +86-15851956577

Category: Drying equipment

Introduction: Working principle The hot air tangent enters the bottom of the dryer, forming a strong rotating wind field driven by the mixer. The paste like material enters the dryer through a spiral feeder. Under the strong action of high-speed rotating stirring p…

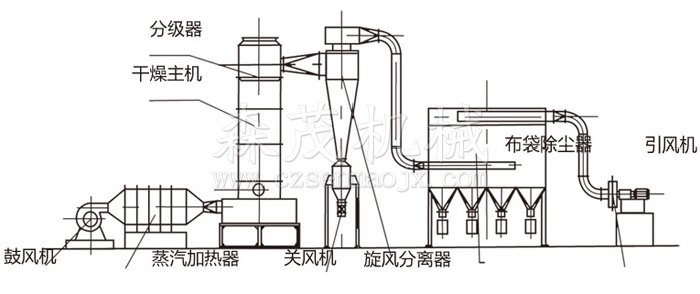

The hot air tangent enters the bottom of the dryer, forming a strong rotating wind field driven by the mixer. The paste like material enters the dryer through a spiral feeder. Under the strong action of high-speed rotating stirring paddles, the material is dispersed under impact, friction, and shear forces. The block like material is quickly crushed, fully in contact with hot air, heated, and dried. The dehydrated dry material rises with the hot airflow, and the grading ring intercepts the large particles. The small particles are discharged from the center of the ring outside the dryer and recycled by the cyclone separator and dust collector. The partially dried or large materials are thrown towards the wall by centrifugal force, and then fall back to the bottom for crushing and drying.

| model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Host inner diameter mm | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Air volume M3/h | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Evaporated moisture kg/h | 12-17 | 40-70 | 80-150 | 150-250 | 230-450 | 300-600 | 600-1000 | 1000-1500 |

| installed capacity kw | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Upper limit of height m | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| cover an area m2 | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note: 1. The water evaporation is the water evaporated per hour when the inlet air temperature is 180 ℃ and the outlet air temperature is 80 ℃. 2. In addition to the above models, special design can be made for users. 3. The above installed capacity is standard matching, which can be significantly reduced according to different power matching of materials.

| Name | stearic acid | Aluminum hydroxide | Zinc Carbonate | monosultap | TMTD | DSD acid | Iron oxide red | Antimony dioxide | Cuprous chloride | White too black |

| inlet air temperature ℃ | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| Initial moisture content% | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Final moisture content % | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Actual drying capacity kg/h | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Name | accelerator |

Oil soluble ink |

Manganese zinc substituted acid |

Phthalocyanine blue |

calcium citrate |

ultrafine calcium carbonate |

mud conditioner |

Sodium Dioxyisocyanurate |

Sodium trioxyisocyanurate |

|

inlet air temperature ℃ |

150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

|

Initial moisture content % |

60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

|

Final moisture content % |

0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

|

Actual drying capacity kg/h |

80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

Previous: None

1. Increase the temperature of hot air entering the towerUnder the condition of constant outlet temperature, the higher the inlet temperature (also known as inlet temperature) of the hot air, the higher the total heat brought in. The more heat per uni…

1. Flash dryer raw material acceleration and drying stageIn the heat transfer medium, particles are at a higher temperature and the air humidity is below 100%. In a short period of time, the surface is heated to the dry material humidity, and the rate…

▲ The flash dryer has multiple feeding devices to choose from, ensuring continuous and stable feeding without any bridging during the process.▲ A dedicated cooling device is installed at the bottom of the flash dryer to prevent material deterioratio…

The internal influencing factors of the efficiency of hollow blade dryers.1. Mixing blade qualityWhen the mixing blades in the hollow blade dryer are damaged, it will seriously affect the working efficiency of the hollow blade dryer. Without the mixin…

A hot air circulation oven is a device that uses circulating hot air to achieve a drying effect. There are generally five models of hot air circulation ovens. They are single door bicycles, two door two cars, two door four cars, three door six cars, a…

The disc dryer is suitable for use in drying projects with high evaporation intensity. On the basis of the basic configuration, a finned heater is added to introduce small flow of hot air into the dryer, absorb the water vapor that escapes from the ma…